MBX®

ELECTRIC VARIOMATIC

Removes rust, paint, underseal and sealants from car panels with ease

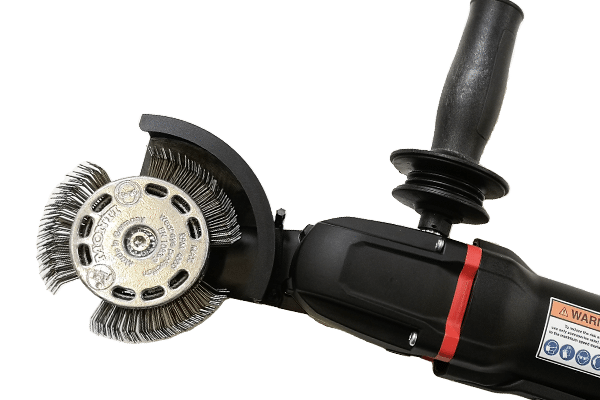

MBX® ELECTRIC VARIOMATIC

The MBX® – the one step tool that easily removes rust, corrosion, oxidation, adhesives, gaskets, layers of paint, undercoating, sealers, vinyl and dresses weld seams. The flexible-wire belts rotate in a patented housing, spinning outward with centrifugal force and working on a cushion of air.

Specially designed bristles are U-shaped staples inserted through a durable nylon belt and provide safe, long lasting performance.

Rapidly removes corrosion and oxidation- both hard and soft material

Rapidly removes corrosion and oxidation- both hard and soft material

Performs on uneven surfaces

Performs on uneven surfaces

Highly flexible in tight areas

Highly flexible in tight areas

No clogging or gumming of bristles

No clogging or gumming of bristles

No grinding or removal of substrate material

No grinding or removal of substrate material

Efficient cutting action – creates angular profile

Efficient cutting action – creates angular profile

Boxes

MBX® Electric Variomatic Set

230V 50/60Hz SE-1041

120V 50/60Hz SE-1141

Downloads

Frequently asked questions

MBX®

What applications is the MBX® suitable for?

The MBX® Technology has been developed for preparing the surface of bodywork panels.

A selection of different MBX® Belts is available that are suitable for specific types of work:

- MBX® Belt coarse, black: Underseal removal

- MBX® Belt medium, ocher: Rust removal

- MBX® Belt fine, green: Paint removal

Also available are blue MBX® Belts with stainless steel bristles, which are ideal for preparing body parts made of stainless steel, aluminum or other nonferrous metals.

Note: The MBX® is generally unsuitable for preparing surfaces other than those of vehicle body parts. The surfaces of steel structures are best prepared using the Bristle Blaster®.

What results does the MBX® Technology deliver?

The MBX® Technology is suitable for cleaning, that is, for removing coatings, rust and paint from car body panels. On such substrates, MBX® Belts – depending on the type of belt – also create a finish similar to that achieved with sandblasting (MBX® Belts coarse and medium).

However, the MBX® Technology is not suitable for preparing steel surfaces, especially when surface cleanliness (e.g. Sa 2½) and roughness specifications have to be met. The Bristle Blaster® should be used for such applications.

Can I also use the MBX® Belts with other drive units?

No! MBX® Belts are specially designed for use with the MBX® drive units. These drive units run at the recommended optimum speed required by the MBX® Belts.

Working at the right speed (idling speed of MBX® Pneumatic = 3,500 rpm, MBX® Electric = 3,200 rpm) guarantees the best results and maximum lifetime for the belts.

What’s more, the in-line design of the MBX® drive units ensures optimum handling and control.

Can a MBX® drive unit also be used with Bristle Blaster® of Die Blaster® Belts?

No! The MBX® drive units are only suitable for use with MBX® Belts.

The design and functionality of Bristle Blaster® and Die Blaster® Belts differ fundamentally from those of MBX® Belts: They are designed to be operated in conjunction with an Accelerator Bar.

As a result, all three types of belt (MBX®, Bristle Blaster® and Die Blaster® Belts) can only be used together with the matching drive unit.

What’s more, the in-line design of the MBX® drive units ensures optimum handling and control.

What servicing work does the MBX® need?

Pneumatic

The compressed-air motor should be regularly oiled. All you have to do is put a few drops of low-viscosity oil into the compressed-air connection. Proper maintenance ensures that the tool enjoys a longer service life and is a precondition for warranty claims.

Electric

Clean the motor housing every time after using the tool and, in particular, blow out the fan with compressed air to remove any dust.

You can find instructions on how to replace the carbon brushes in the user manual in the section headed Maintenance. All repairs should be carried out only by specialists trained in the repair of power tools or by other appropriately qualified tool servicing staff.

Where can I find instructions on how to use the MBX®?

It is crucial that you use the MBX® correctly, so that you obtain the results that you want. You can find appropriate instructions in the user manual enclosed with every set. We also recommend that you watch our application film.