Removing mill scale with the power tools from MontiPower

What is mill scale?

Mill scale is iron oxide that is formed on a steel surface that has been hot rolled. During hot rolling, due to the high temperature involved, oxide is formed over the entire steel surface. The flaky surface increases as hot rolling progresses. The spots are often hard, but at the same time very fragile. The combination of the high temperature and the large amount of pressure used during rolling eventually results in a blue-grey surface, which we call the mill scale.

Should mill scale be removed from steel?

We now know what mill scale is and how it is formed, but is the mill scale actually harmful, and should it be removed? In theory, the mill scale could be a well adhering layer that serves as a perfect protective layer on steel. Unfortunately, in practice, this is not the case.

The mill scale is not connected to the underlying surface. The oxides are pressed into the object with great force, however they are not actually attached to the surface but to the mill scale. Over time, for example during processing of the material, the mill scale will slowly but surely come loose, causing it to lose its protective effect. A tricky situation, since any coatings that has been applied directly to the mill scale will also be removed from the object. It is therefore important to remove the mill scale before processing the product and applying the coating, since sooner or later it will come loose.

Why is it important to remove mill scale prior to painting?

With the above mentioned loosening of the mill scale, not only does it lose its protective function, but paint and coatings applied directly to the scale will also be removed from the object in this way. Therefore, it is very important to remove the mill scale before applying a new coating or paint layer on the steel object, in order to prevent the peeling of the paint.

How to remove mill scale prior to painting?

In order for a paint layer to adhere as well as possible, it is very important to first successfully remove any mill scale. For the removal of mill scale prior to the application of a new paint layer, there are several techniques available. But what are these techniques for removing mill scale actually, how do they work, and what are their advantages and disadvantages?

Removing mill scale by corrosion

In the past, often in the construction and maritime market, it was often decided to let rust form on the mill scale. By keeping the objects outside, the mill scale was affected by the weather, which resulted in a layer of rust. A removal method that takes a very long time and also a lot of space. This is not the only drawback. By allowing the mill scale to rust, the object is also severely affected and even damaged. For this reason, various techniques have been developed over the years to remove mill scale from metal pipes or plates.

Chemical removal of mill scale from steel

One of the most common ways to strip steel from mill scale is chemical removal. A thorough way of removing that also works very quickly and efficiently. When the mill scale is chemically cleaned, the layer is dissolved in acid – often hydrochloric, phosphoric or oxalic acid. A major disadvantage of chemical cleaning is that it is difficult to estimate when the chemical reaction of the acid will stop. If the reaction continues for too long, the object will be damaged by the aggressive effect of the acid and, moreover, will immediately start to rust again. This chemical reaction can only be stopped by adding other substances. Chemical cleaning can therefore be a quick and efficient method for removing the mill scale, but it also has its drawbacks. Moreover, this is not the only drawback.

Disadvantages of removing mill scale

Besides the fact that chemical removal of the mill scale can damage the object itself, it can also be dangerous for humans, animals and the environment. Hydrochloric acid is extremely aggressive and can cause nasty wounds when in contact with human skin. In addition, when working with hydrochloric acid, a lot of fumes can be released, which is also very dangerous. The released fumes spread through the air and can damage the environment in many ways. In addition, when this fume comes in contact with water, it is fatal to fish and other aquatic animals.

Fortunately, the chemical method is not the only option for removing mill scale from steel. For example, the mill scale can also be cleaned using grit blasting or abrasive blasting. Although this does not have the harmful effect that chemical cleaning does, these methods for removing the mill scale also have their drawbacks. For example, not all objects are suitable for blasting or grinding. In addition, during blasting or grinding, beads of metal will spurt all over your work. These spatter stick to the place they fall upon. As a result, it is not easy to have a completely clean surface after removing the mill scale. All in all, the removal of the mill scale requires a lot of work and preparation, so it is recommended that this is always carried out by a professional.

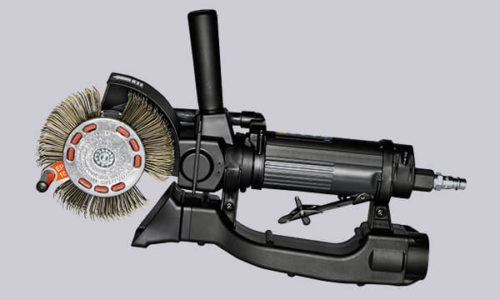

Another way to remove mill scale: the MontiPower Bristle Blaster®

We can imagine that you prefer to remove the mill scale yourself, despite all the disadvantages associated with it. In this way you are not dependent on an external party, and you can also save costs. How nice would it be if there were a machine for removing the mill scale that you can operate easily and quickly yourself? We have good news for you: those tools are available! With the Bristle Blaster® from MontiPower you can remove the mill scale from your steel surface in no time. Depending on the type of steel, Monti’s power tools can thoroughly and yet skillfully remove the mill scale from the steel. After the mill scale has been removed, a flawless surface is created, which serves as the perfect bonding layer for a new coating.

How do you remove mill scale with the MontiPower removal tools?

The Bristle Blaster® from MontiPower combines simplicity with a perfect result. The simple operation of the manually operated tool ensures that you can remove the mill scale from your steel yourself in no time. How do you remove the mill scale? The Bristle Blaster® features a rotating brush with specially designed, patented curved tips. Because these curved brush tips are released with great force from behind the accelerator bar of the Bristle Blaster®, the tips immediately retract from the surface. This not only removes the mill scale perfectly, but also creates a beautiful, new bonding layer due to the imprint of the points. The technology of the power tools makes the Bristle Blaster® not only the ideal tool for removing mill scale, but also, for example, an ideal alternative to sandblasting. It is therefor used for many markets, such the welding industry, industrial sector, or the marine sector. Besides mill scale removal, our surface preparation tools also remove rust, paint, copper slag, or other dirt.

The Bristle Blaster® combines the ability to produce an abrasive blasted finish with the high mobility and flexibility of a portable hand-held tool.

This patented technology is the only feasible solution for maintenance in confined and hard-to-reach areas. It’s easy to operate and removes the need for enclosures, reprocessing or disposal of grit.

The Bristle Blaster® Pneumatic Tool is ATEX approved and can be safely used in Zone 1 (potentially explosive atmospheres) applications.

The Bristle Blaster® Electric Tool ensures excellent flexibility thanks to standard power supply ratings (230 V/120 V).

Portuguese (Portugal)

Portuguese (Portugal) Dutch

Dutch Spanish

Spanish French

French German

German English

English