Great news from our partner in the UK: Cactus Industrial ltd. has won a significant contract to supply our Bristle Blasting® technology to the Ministry of Defence. Having gone through extensive trials at Her Majesty’s Naval Base at Portsmouth, the Royal Navy will use the Bristle Blaster® to treat metal surfaces exposed to sea water for both its surface vessels and its submarine fleet.

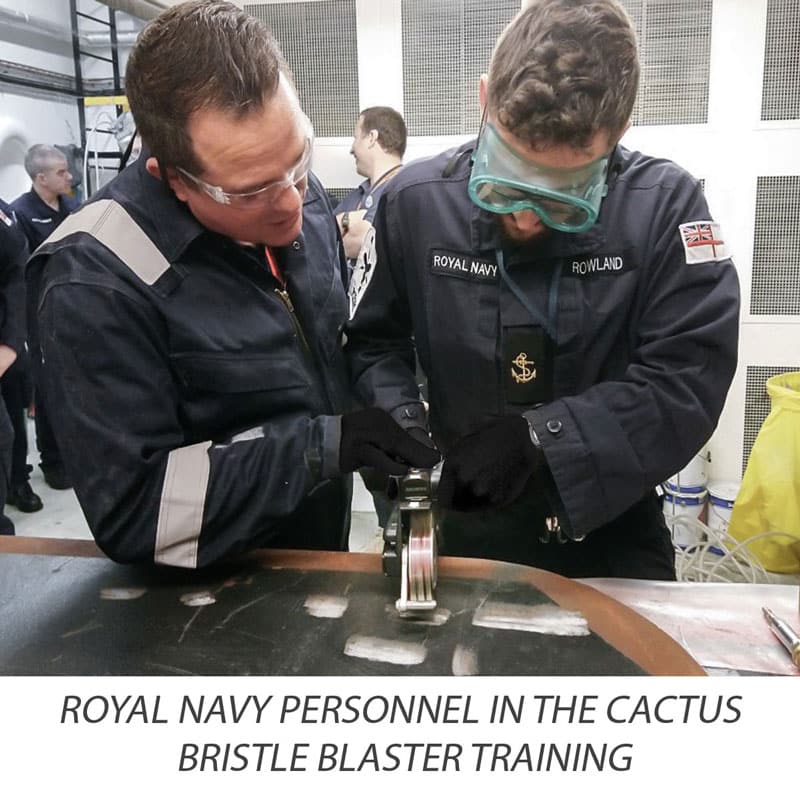

Our colleagues from Cactus Industrial gave training to Navy personnel and contractors on the effective use of the Bristle Blaster® in preparing surfaces affected by the marine environment. The purchase order was placed and more orders are expected to come.

Quoting Jamie Gallagher, Chief Executive of Cactus Industrial, “We have now trained and educated Royal Navy personnel in how to use the Bristle Blaster® for optimal surface preparation for maintaining the UK’s sea-going fleet. Blasting without grit technology is one of the most effective ways to ensure that Royal Navy ships and submarines are prepared to face the harsh marine environment with as little downtime as possible.”

Also Paul Waugh, Warrant Officer Class 1, Royal Navy, claimed that the Bristle Blasting Technology will considerably reduce time and make preservation efforts during a base maintenance period (BMP) more effective.

Cactus Industrial Ltd. is the sole licensed UK and Ireland distributor for the Bristle Blasting Technology. The company already deploys the technology and coatings in a range of sectors, particularly in the upstream oil and gas industry. The contract with the British Ministry of Defence marks a significant move into military application of the Bristle Blaster®.

Frits Doddema

Author of MontiPower®

Leadership | Sales | Marketing | Development

He is passionate about alternating solutions which make a true difference. Nothing is impossible is his credo. To make the impossible possible, Frits and the management believe in just one idea to make it happen and to turn the company in a great firm. The innovative approach for game-changing blasting and paint solutions is hands-on keeping in mind the difficult field circumstances for operators, respecting nature and long term costs. The mission is to avoid any disagreement over quality of prep work and coating. Frits and his team push for non-hazardous long term corrosion prevention solutions to overcome any hassle out of a coating job ensuring the best possible bond. The world’s best coatings deserve the world’s best surface preparation. Like in daily life, preparation is everything. From different perspectives like Safety, Health, Ergonomics, Productivity, Recyclability, Co2 neutrality of the plant and the coating process, Substrate Compatibility, Corrosion Resistance, Frits and team are driven to come with improved unique contribution solutions to existing and new end markets.

English

English