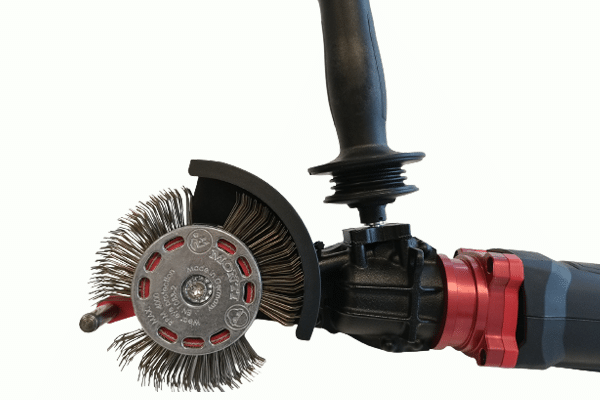

BRISTLE

BLASTER®

ULTIMATE CORDLESS

The new cordless technology for the Bristle Blaster® including the Safety switch. This makes it easier to work in areas that are difficult to access, for instance at great heights.

BRISTLE BLASTER® ULTIMATE CORDLESS

The new cordless technology for the Bristle Blaster® including the safety switch. It includes the anti-vibrating handle and a new robust fronthead.

Chargers are part of the Cordless Alliance System; you can

Chargers are part of the Cordless Alliance System; you can

combine machines, battery packs and chargers of different

manufacturers without any problems

Approx. 25 minutes surface preparation time for 8Ah/18V

Approx. 25 minutes surface preparation time for 8Ah/18V

Adjustable accelerator bar to fit difficult to reach objects

Adjustable accelerator bar to fit difficult to reach objects

2200 rpm for single belt operation

Specifications

Accessories

Battery LIHD

18V, 5,5 Ah

ZU-600

Battery LIHD

18V, 8,0 Ah

ZU-602

Battery Fast Charger for CAS LiPower/ LiHD batteries

ZU-601

Boxes

Bristle Blaster® Ultimate Cordless Set, packed into a blow mould storage case

SB-700-BMC

standard packaging

offshore case

small

offshore case

large

Downloads

Frequently asked questions

Bristle Blaster® Ultimate Cordless

What results does the Bristle Blaster® Cordless Technology deliver?

The cordless Bristle Blaster® Technology is capable of removing corrosion and coatings quickly and thoroughly. At the same time, the Bristle Blaster® creates surface preparation grades comparable with Sa 2½–3 and roughness levels of up to 120 µm Rz at aluminium

Example: Roughness levels of 65–83 µm were achieved on a pipe made of API-5L-X42 steel with rust grade D.

What is the working time of the Bristle Blaster® Cordless?

The working time of the Bristle Blaster® per m2, depends on the following factors:

- Hardness and quality of the base material

- Rust grades present (A, B, C, D)

- Coatings applied (type, thickness)

- Scale layer

- Adhesive residues

Example: A working speed of 1.1 m² per hour was achieved on a pipe made of API-5L-X42 steel with rust grade D.