Noiseless

The problem:

Too much noise during grit blasting

Abrasive grit blasting produces noise levels that can cause permanent hearing loss in unprotected workers and others close to the blasting process. The main source of noise is the discharge of compressed air at the blast nozzle.

Can’t you blast noiseless?

The solution:

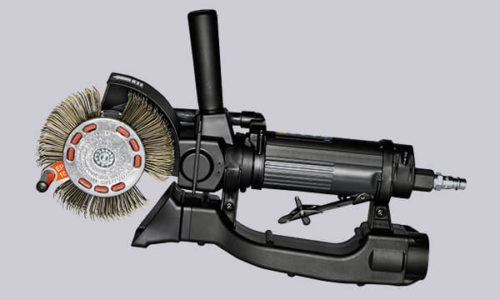

Bristle Blaster® Pneumatic with noise reduction

The patented Bristle Blaster® Technology is used in numerous industries and especially where conventional blasting methods are not possible or uneconomic. The Bristle Blaster® Pneumatic comes with noise reduction, which makes working with it almost noiseless.

The Bristle Blaster® combines the flexibility and the short set-up times of a hand-held tool with the results otherwise achieved with blasting: Surface preparation grades comparable with Sa 2½–3 and roughness levels of up to 120 µm Rz. This makes our technology the perfect surface preparation method for spot-repairs, touch-up jobs and preparing welds.