MBX®

ELECTRIQUE

Elimine facilement la rouille, la peinture, les produits de protection du soubassement et les agents d’étanchéité des panneaux de voiture

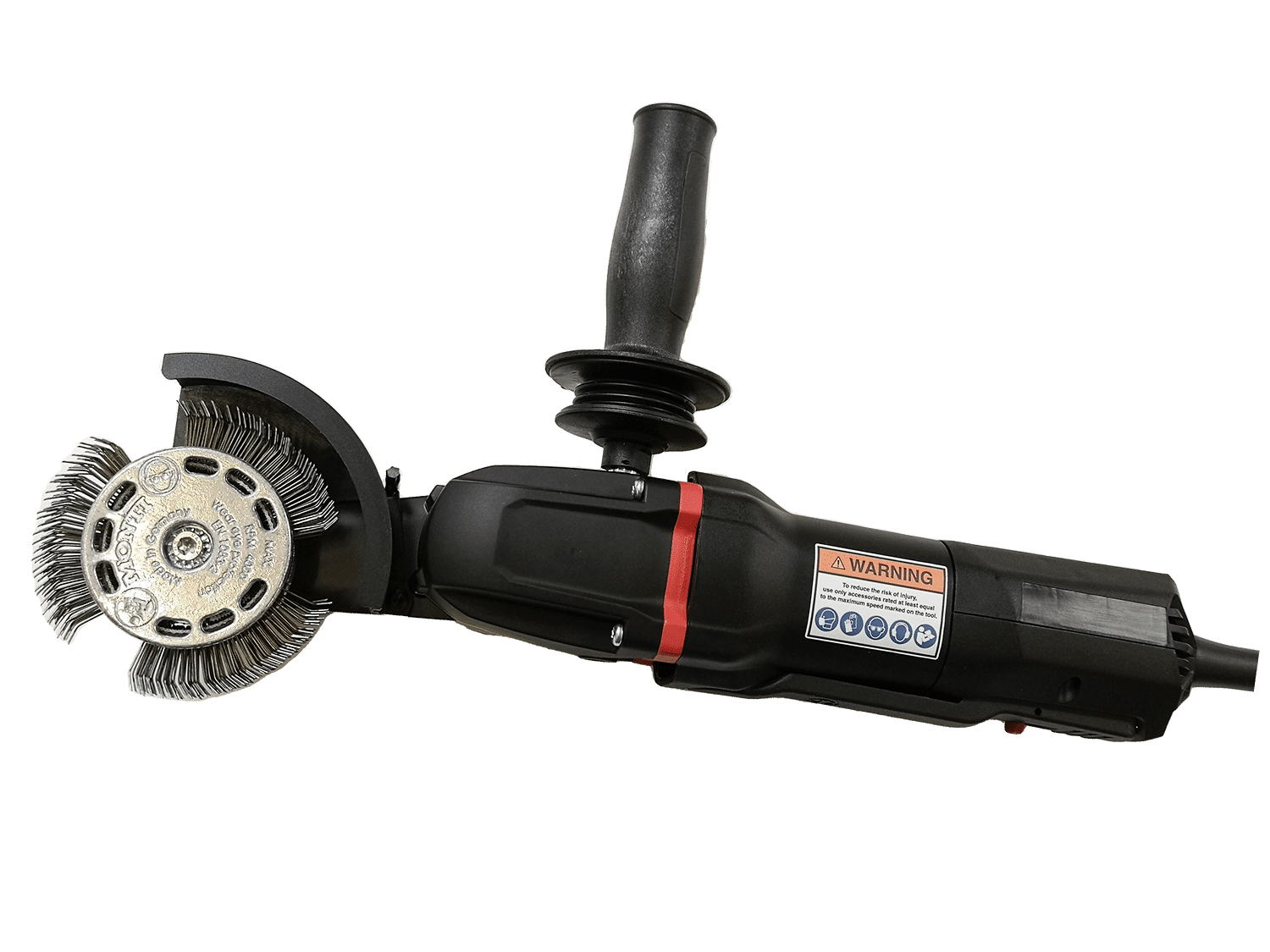

MBX® ELECTRIQUE

Le MBX®, l’outil une étape qui éliminer facilement la rouille, la corrosion, l’oxydation, les adhésifs, les joints, les couches de peinture, les sous-couches, les agents d’étanchéité, le vinyle et les joints de soudure habillés. Les courroies métalliques flexibles tournent dans un coffrage breveté, tournant vers l’extérieur avec la force centrifuge et sur un coussin d’air.

Les poils spécialement conçus en forme de U insérés à travers une courroie durable en nylon fournissent des performances durables et sûres.

Elimine rapidement la corrosion et l’oxydation des matériaux durs et mous

Fonctionne sur des surfaces irrégulières

Hautement flexible dans les zones confinées

Aucun encrassement ni gommage des poils

Aucune abrasion ni élimination du matériau du substrat

Opération de coupe efficace

SPECIFICATIONS

COURROIES

ACCESSOIRES

PIERRE DE RE-AFFUTAGE

SYSTEME D’ADAPTATEUR 23 MM

SYSTEME D’ADAPTATEUR 11 MM

BOITES

ENSEMBLE MBX® ELECTRIQUE

QUESTIONS FREQUEMMENT POSEES

MBX®

What applications is the MBX® suitable for?

The MBX® Technology has been developed for preparing the surface of bodywork panels.

A selection of different MBX® Belts is available that are suitable for specific types of work:

- MBX® Belt coarse, black: Underseal removal

- MBX® Belt medium, ocher: Rust removal

- MBX® Belt fine, green: Paint removal

Also available are blue MBX® Belts with stainless steel bristles, which are ideal for preparing body parts made of stainless steel, aluminum or other nonferrous metals.

Note: The MBX® is generally unsuitable for preparing surfaces other than those of vehicle body parts. The surfaces of steel structures are best prepared using the Bristle Blaster®.

What results does the MBX® Technology deliver?

The MBX® Technology is suitable for cleaning, that is, for removing coatings, rust and paint from car body panels. On such substrates, MBX® Belts – depending on the type of belt – also create a finish similar to that achieved with sandblasting (MBX® Belts coarse and medium).

However, the MBX® Technology is not suitable for preparing steel surfaces, especially when surface cleanliness (e.g. Sa 2½) and roughness specifications have to be met. The Bristle Blaster® should be used for such applications.

Can I also use the MBX® Belts with other drive units?

No! MBX® Belts are specially designed for use with the MBX® drive units. These drive units run at the recommended optimum speed required by the MBX® Belts.

Working at the right speed (idling speed of MBX® Pneumatic = 3,500 rpm, MBX® Electric = 3,200 rpm) guarantees the best results and maximum lifetime for the belts.

What’s more, the in-line design of the MBX® drive units ensures optimum handling and control.

Can a MBX® drive unit also be used with Bristle Blaster® of Die Blaster® Belts?

No! The MBX® drive units are only suitable for use with MBX® Belts.

The design and functionality of Bristle Blaster® and Die Blaster® Belts differ fundamentally from those of MBX® Belts: They are designed to be operated in conjunction with an Accelerator Bar.

As a result, all three types of belt (MBX®, Bristle Blaster® and Die Blaster® Belts) can only be used together with the matching drive unit.

What’s more, the in-line design of the MBX® drive units ensures optimum handling and control.

What servicing work does the MBX® need?

Pneumatic

The compressed-air motor should be regularly oiled. All you have to do is put a few drops of low-viscosity oil into the compressed-air connection. Proper maintenance ensures that the tool enjoys a longer service life and is a precondition for warranty claims.

Electric

Clean the motor housing every time after using the tool and, in particular, blow out the fan with compressed air to remove any dust.

You can find instructions on how to replace the carbon brushes in the user manual in the section headed Maintenance. All repairs should be carried out only by specialists trained in the repair of power tools or by other appropriately qualified tool servicing staff.

Where can I find instructions on how to use the MBX®?

It is crucial that you use the MBX® correctly, so that you obtain the results that you want. You can find appropriate instructions in the user manual enclosed with every set. We also recommend that you watch our application film.

Portugais - Du Portugal

Portugais - Du Portugal Néerlandais

Néerlandais Espagnol

Espagnol Français

Français Allemand

Allemand Anglais

Anglais