Dr. Prepper

No. 3

Defining Mechanical Surface Preparation Standards with Power tools

In this 3rd edition of Dr. Prepper we’ve invited Roman Dankiw and Daniel Fosdike to share their knowledge and experience.

Roman Dankiw is Principal Inspection Consultant at Asset Inspection Consultants Pty LTd, Adelaide and Daniel Fosdike is Senior Structural Engineer of ASC Shipbuilding, Adelaide, Australia.

This ‘RED PAPER’ examines current mechanical surface preparation methods with power tools and standards to help de ne requirements for applicators using less costly and simpler methods of inspection.

The regular RED PAPER from MontiPower®. Full of nice to know – and need to know – facts about the most optimal surface preparation since 1987.

Power tool cleaning of steel surfaces prior to coating application is permitted in certain circumstances on Shipbuilding projects. Particularly where abrasive blasting poses hazards to installed electrical and mechanical equipment in-situ, and where access is restricted for abrasive blasting, or for small spot repairs.

The specification requirement for mechanically prepared (Power tool Clean) surfaces is for the surface to meet St3 of AS 1627.2 and to provide a consistent angular surface profile of 50-100 microns in critical areas (Bilges, immersed tanks). This requirement is to ensure that the prepared areas are not polished as required by the paint manufacturer’s recommendation.

The power tool cleaning standard specified in AS1627.2 St3 [1], does not specify a surface profile as such and refers to descriptions of cleanliness with pictorial standards as visual aids.

To measure the surface profile with replica tape (Testex) [2] across numerous localised repair areas poses a costly and labour-intensive inspection process. Numerous spot repairs are necessary in bilge and immersed tank spaces due to coating damage sustained during construction and consolidation joints.

Abrasive blasting is not practical in these spaces due to machinery and equipment installed and limited dust/abrasive extraction is possible in restricted spaces.

Trials on different material grade plates and different Power tool Cleaning preparation methods were used to compare replica tape readings with visual appearance and texture. A coating of approximately 200-300 microns of abrasion resistant Aluminium epoxy was applied, which is used in the bilges and machinery spaces. This coating was later assessed with adhesion pull o tests to ascertain coating adhesion performance against differently prepared surfaces.

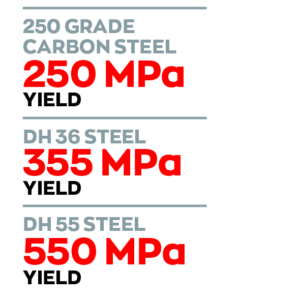

Test plates (approximately 200mm x 200mm x 5mm) were prepared from 3 different material grades used on the project. They have different hardness properties, which usually affects the degree of cleaning required:

The initial condition of the plates was Grade A-B according to AS 1627 Part 4, and were prepared using rotating machine tools using 3 different abrasive discs, to achieve an approximate 50 micron surface profile using replica tape:

GRINDER

SANDING DISC

#36 GRIT

FLAPPER DISC

GRINDER

#40 GRIT

BRISTLE

BLASTER® BELT

All 3 different material grade plates were subjected to the 3 different abrasive discs, noting a grit blast comparator placed to obtain an idea of the textural feel by hand rather than a visual one.

After the surfaces were prepared they were coated with 200-300 microns of the Aluminium Abrasive resistant epoxy coating. Three pull off testing dollies were glued to the cured coating (after one week).

All 9 plates were subjected to pull off adhesive tests [1], with most failures occurring cohesively in the coating, with a small percentile with less than <20% of the dolly areas exhibiting adhesive failures to the prepared surfaces for each preparation method.

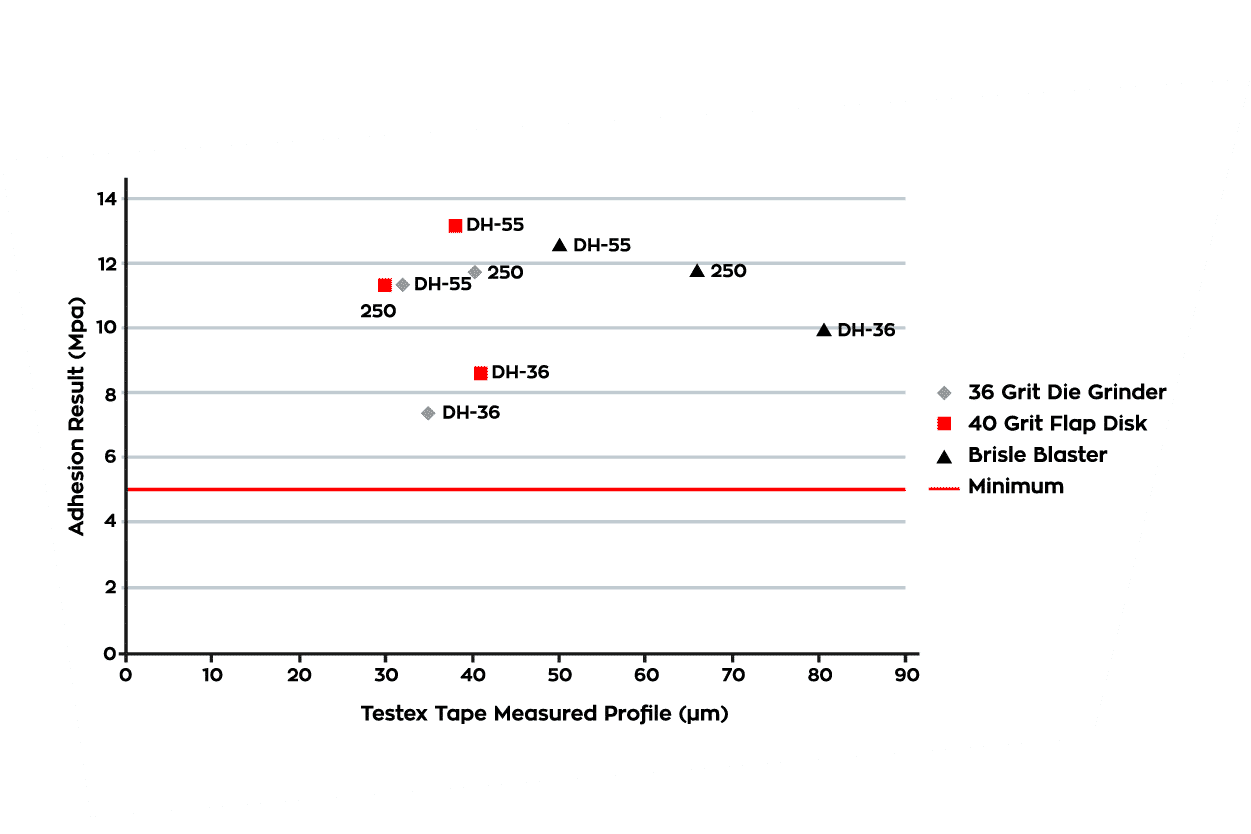

The adhesion values were well above the minimum 5 Mpa requirement for the coating using all preparation methods. The Bristle Blaster® gave less variation of pull off Adhesion values than the other 2 methods, (see graphic). The Bristle Blaster® gave a variation of approximately 2-3Mpa, whereas the #36 grit grinder and #40 flapper disc grinder variations were greater (approximately 5Mpa).

When comparing preparation methods and adhesion values across the 3 different material groups, the DH 36 adhesion values appeared in the lower adhesion ranges, with the 250 and DH 55 grade material pull off adhesion values appearing in the higher ranges.

The surface profile

values of the

BRISTLE BLASTER®

were consistently

above 50 MICRONS

Whereas the other methods measured profiles ranging from 30- 40 microns, below the manufacturer’s recommendation.

However, the lower measured profiles of the grinding discs were still able to produce compliant adhesion values.

The power tool cleaning standards specified by the paint manufacturer list the following as acceptable for spot or localised repairs:

PT(JSRA SPSS:1984)-[4]

SSPC-SP11-[5]

However, some shipbuilding coating specifications list the applicable standard for power tool cleaning as AS1627.2 St3 (ISO 8501-1), which is not consistent with the coating manufacturer’s recommendations.

When comparing the 3 standards, only the SSPC-SP11 specifies a minimum surface profile value of 1 mill (25 microns).

SSPC-SP11 section 3.4 provides more definitive surface preparation methods for producing a surface profile and refers to the use of replica tape to measure surface profile as detailed in section A.6. The visual standard (VIS-3) images are consistent with the descriptions, with the quality of the preparation photographs being very good.

The JSRA SPSS also provides good quality photographs that are consistent with the surface preparation descriptions, however with no mention of surface profile values.

In comparing the surface preparation methods used in the trial, the Bristle Blaster® disc gave the better surface profile and a more consistent surface texture than the rotary flapper and sanding discs. The Bristle Blaster® is more suited to preparing welds and edges due to the wire prongs being more flexible to follow shapes and contours.

The visual appearances across the ISO 8501-1, SSPC-SP11 and JSRA SPSS mechanical preparation standards are significantly different, particularly ISO 8501-1, where the description for St3 preparation compared to the image

is inconsistent with ‘very thorough cleaning producing a metallic sheen’.

The rotary and sanding discs gave a lesser profile compared to the Bristle Blaster®, but visually appeared brighter and shinier, indicating a more polishing effect.

The Pull-off adhesion test results do not show a clear correlation between the adhesion pull off values across the 3 preparation methods against profile height (microns) as shown in figure 11, other than the range (spread) of adhesive values was narrower for the Bristle Blaster® compared to the grinding discs.

The adhesion values across the 3 different material grades were not showing distinctive groupings other than DH36 material showing the lowest band of adhesion values across all preparation methods. No clear explanation could be deduced on why the 250 grade and DH55 materials were producing higher adhesion values than DH36, considering that the 250 grade material is a softer hardness grade, compared to the DH55 being the hardest grade.

The Bristle Blaster® surface appearance closely resembles the grit comparator and measured surface profile values on the test plates.

The Bristle Blaster® was able to produce a consistent profile meeting the shipbuilding coating specification on bare steel and more consistent coating adhesion properties across a variety of material grades, and is more suitable for welds and contours.

The comparison of the SSPC, AS/ISO and JSRA pictorial standards are widely different from the appearances shown in the trials.

The SSPC-SP11 standard and corresponding SSPC-VIS 3 pictorial images provide a greater ability for visual assessment of prepared surfaces due to better representational images and more detailed information contained in the pictorial standards.

Shipbuilding coating specifications need to be written to be consistent

with the coating manufacturer’s recommendations to ensure consistency and clarity on acceptance criteria of surface preparations. The ISO 8501-1 pictorial standard is not considered appropriate to use in lieu of SSPC-SP11 or JSRA SPPS due to the pictorial quality of the St3 power tool cleaning not consistent with its description of ‘very thorough cleaning producing a metallic sheen’. The Bristle Blaster® texture closely resembles the grit comparator and can be used in lieu of using replica tape for surface preparation profile assessment for localised or spot repairs on bare steel.

Roman Dankiw, Principal Inspection Consultant of Asset Inspection Consultants Pty LTd, Adelaide.

Roman has had over 35 years’ inspection experience in the construction and maintenance of ships, submarines, oil and gas facilities, pipelines and civil structures. His company Asset Inspection Consultants provides inspection services to industry. Roman holds inspection certifications in coatings (NACE level 3), welding (WTIA, IIW), pressure equipment (AICIP) and Fireproofing & Insulation (Icorr level 2). Roman is the Chair of the recently reformed ACA Defence Technical Group and is a past ACA National President (2010).

Daniel Fosdike, Senior Structural Engineer of ASC Shipbuilding, Adelaide, Australia.

Daniel is the Senior Engineer for materials and coatings at ASC Shipbuilding who greatly assisted in the collection and collation of technical data for this paper.

In this role, Daniel is responsible for the prevention of corrosion on the Hobart Class Air Warfare Destroyers currently under construction for the Royal Australian Navy. Daniel is Co-chair of the ACA Defence Technical Group and ACASA Branch Committee Member. Daniel is also a NACE Level 3 Coating Inspector.

REFERENCES:

[1] AS1627.2- Metal finishing – Preparation and pre-treatment of surfaces Part 2: Power tool cleaning.

[2] AS3894.5- Site testing of protective coatings, method 5: Determination of surface profile.

[3] ISO 4624- Paints and varnishes – Pull-off test for adhesion.

[4] Japanese Shipbuilding Research Association (JSRA)- Standard for the preparation of steel surface prior to painting

[5] The society for protective coatings – Surface preparation specification no. 11 – Power tool cleaning to bare metal.

Download Dr. Prepper No. 3

You can also download the complete Dr.Prepper No. 1 and Dr. Prepper no. 2

Portugais - Du Portugal

Portugais - Du Portugal Néerlandais

Néerlandais Espagnol

Espagnol Français

Français Allemand

Allemand Anglais

Anglais