Dr. Prepper

edition 6

Bristle Blasting VS Grit Blasting: Processes for Field Pipeline Surface Preparation

In the 6th edition of Dr. Prepper we take a look at Robert J Stango, Ph. D. comparative study between the Briste Blasting process and the Grit Blasting process. In this edition we take a look at the results of both processes produced when utilized.

The results shown in this Dr. Prepper are the result of the abrasive blasting process. Both processes are schematically illustrated, and the final results are illustrated by a photomicro-graph. A chart illustrates the difference in lifespan of coating applied after either blasting process.

The results that the blasting processes are objectively noted throughout this Dr. Prepper. We close this edition with a comparative conclusion by Robert J Stango, Ph. D. himself.

The regular RED PAPER from MontiPower®. Full of nice to know – and need to know – facts about the most optimal surface preparation since 1987.

Bristle Blasting

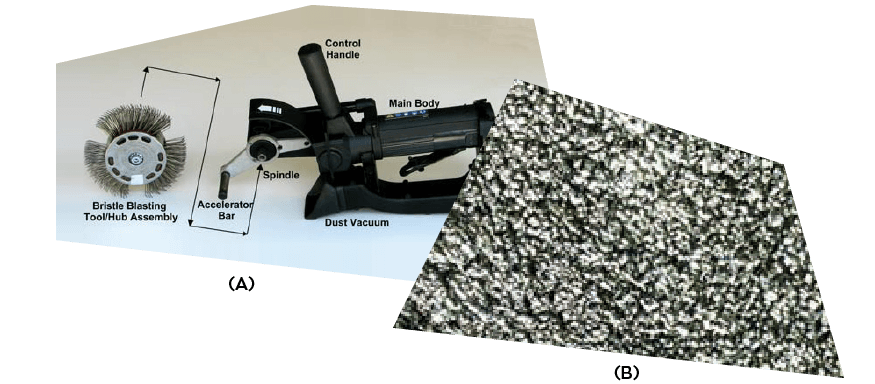

The Bristle blasting tool (see Figure 1A) has a brush-like appearance, and consists of sparsely populated wires having sharpened tips. As the spindle rotates, each bristle tip strikes the metallic surface and immediately retracts/rebounds, thereby causing a multitude of impact craters that are similar to those formed during grit blasting operations. This repetitious process both removes the corrosive layer and generates a fresh surface having the coarse pattern shown in Figure 1B.

Figure 1 (A) Bristle blasting power tool system (pneumatic version shown), and (B) characteristic surface generated by bristle blasting process.

Grit Blasting

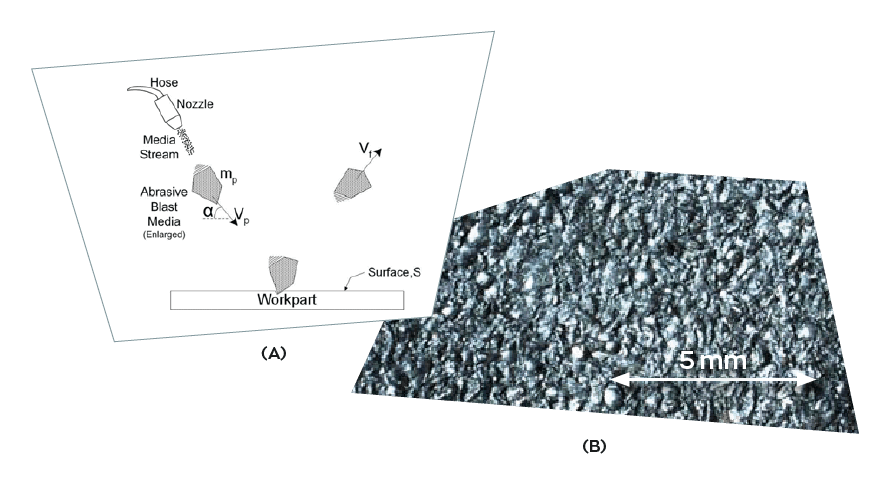

Grit blasting processes utilize “loose” abrasive grains, which are propelled toward the target surface, as shown in Figure 2A. Upon impact, each abrasive grain forms a “crater-like” micro-indentation, which simultaneously removes friable corrosion and exposes fresh substrate.

Figure 2 (A) Schematic of abrasive blasting process, and (B) characteristic grit blast surface generated by G16 steel media.

As depicted in Figure 2B, the repeated micro-indentations generate a surface texture that consists of “peaks and valleys”, which are associated with the recurring impact and deformation of the workpart surface.

Bristle Blasting

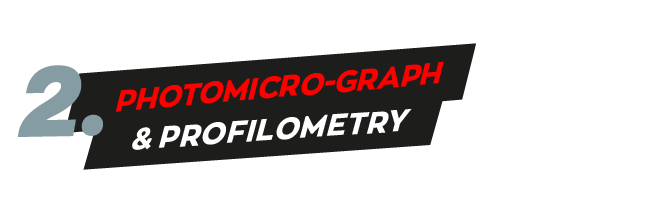

Figure 3 Photomicro-graph and profilometry Bristle Blasting

Grit Blasting

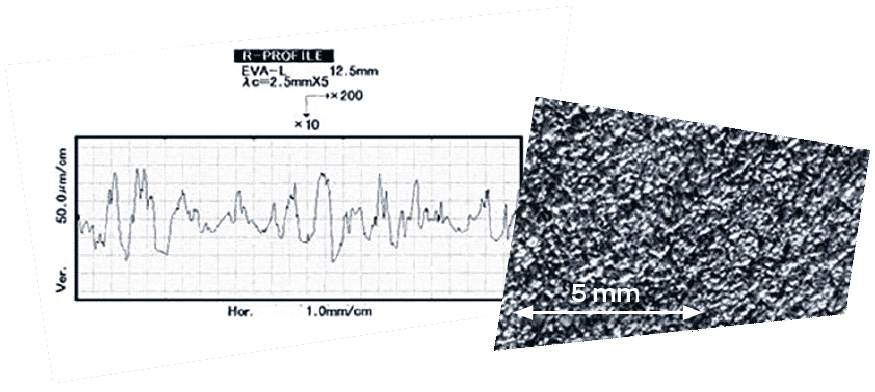

Figure 4 Photomicro-graph and profilometry Grit Blasting

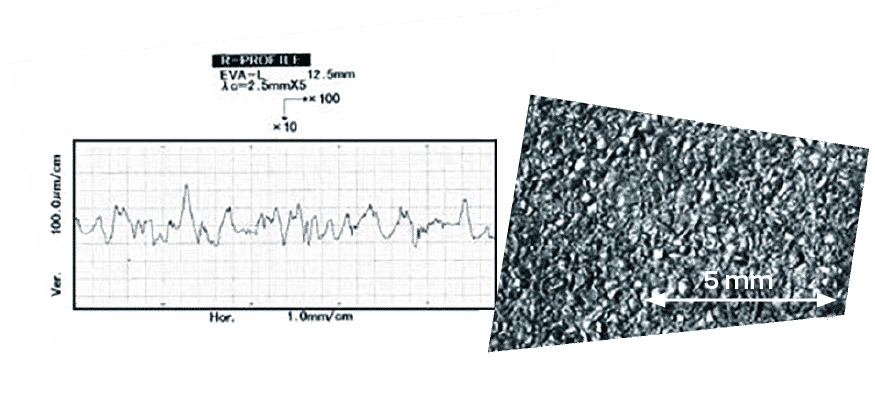

In comparison to the traditional blasting process, Bristle Blasting significantly prolongs the lifespan of the adhesion of the coating.

Figure 5 Coating Lifespan Chart Bristle Blasting & Grit Blasting

The Bristle Blasting technology is a perfect alternative to conventional blasting methods. The related tool, the MontiPower® Bristle Blaster®, is capable of generating an abrasive blast finish on a metal surface, simultaneously removing corrosion, coatings and mill scale.

Download Dr. Prepper No. 6

You can also download the complete Dr. Prepper edition: